Utilizing the pipe alignment tools is crucial when fit-up and tack-welding piping joints for production welding. including other connections. This guide will offer practical tips on how to optimize your pipe alignment tool system and guarantee smooth processes throughout your projects. If you are to follow these steps, you will be able to step up the precision of your work and your pipe connections’ duration. resistance to wear.

Step 1: Inspect Your Tools

One of the most important things to remember when going through any welding process is that your pipe alignment tools need to be checked first for any signs of damage. In particular, look for signs of wear and tear, impacts, or any other kind of defects that may influence the usage of the tool. When the pipe alignment tool is inaccurate, the alignment is affected, which may affect joint quality and lead to failure. You must schedule the pipe alignment tool system to be checked and serviced regularly so that you can have a proper alignment for your welding projects.

Step 2: Secure the Pipe

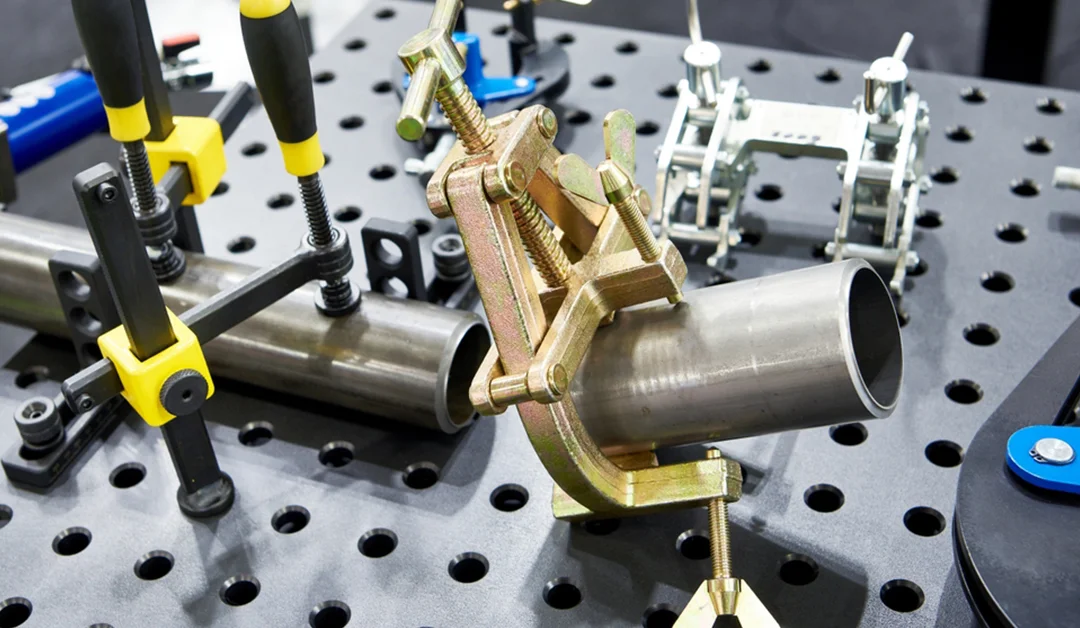

Once you have ensured that your tools are in good condition, the next step is to secure the pipe. Position the pipe securely within the clamps of the weld pipe alignment system. This step is critical as it prevents any movement during the welding process. A stable and secure pipe ensures that the alignment remains consistent, reducing the risk of errors and defects in the weld. Make sure the clamps are tightened adequately to hold the pipe firmly in place.

Step 3: Adjust for Proper Alignment

After securing the pipe, use the adjustment features of your pipe alignment tool to achieve the correct alignment. Proper alignment is key to minimizing the risk of weld defects and ensuring a strong, durable connection. Take your time to adjust the pipes until they are perfectly aligned. This step may require fine-tuning, but it is essential for achieving precise and accurate fit-ups. A well-aligned pipe fitting alignment system can significantly improve the quality of your welding projects.

Step 4: Monitor Throughout the Process

As the welding process is being conducted, alignment should be observed and monitored frequently. Any deviation can lead to a significant deviation from the quality of the weld zones. Occasionally, compare the current positions and make corrections when the accuracy is compromised at different stages of the process. Thus, you can avoid misalignment of such members and make sure that the welds obtained are sufficiently durable.

Final Thoughts!

The pipe alignment tools are a very crucial aspect that ought to be mastered well to have excellent fit-ups and best welds. This way, this step-by-step guide will help you improve the performance of the pipe alignment tool system and guarantee project success. In this pipeline alignment system service, Fit Rite Fast delivers high-quality pipe fitting alignment system products and consulting services for your projects. Whether it is a simple DIY task or a complex industrial assignment, our tools and knowledge will assist you in attaining strong and lasting joints. Choose us Fit Rite Systems for the best pipe weld alignment system that will providing the ultimate in speed and accuracy. A good fit makes a good weld.