The pipe fitting and fabrication sector in Qatar plays an essential role in maintaining its expanding infrastructure development alongside rapidly expanding industrial activities. Perfect fit-ups as the principal obstacle in pipe fitter and fabricator work because improper alignment leads to expensive delays along with safety threats and enhanced material wastage.

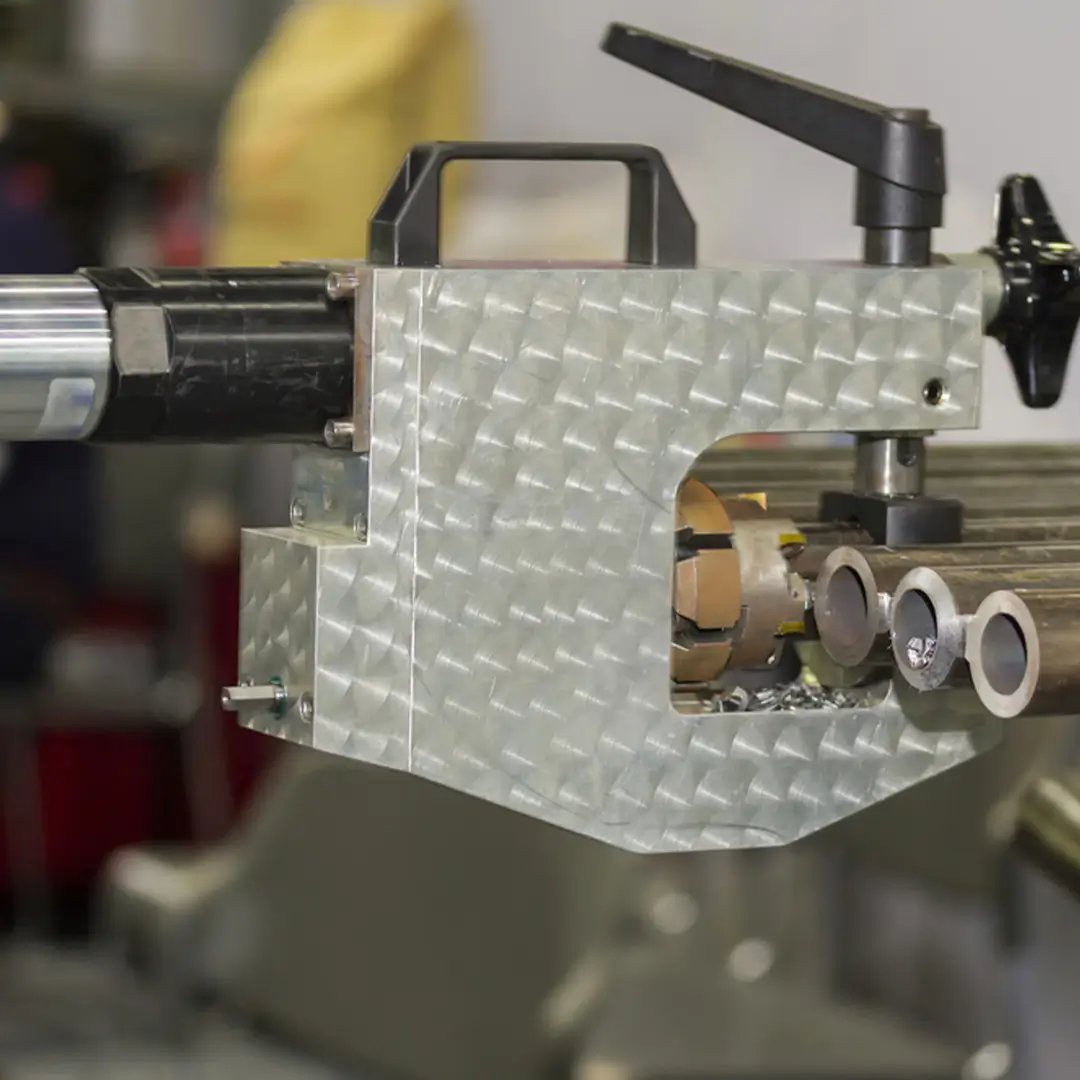

The FIT RITE System changes how pipe fitters and fabricators execute flawless fit-ups and improves their efficiency while boosting precision.

No Helper or Assistance Required for Perfect Fit-Ups

The traditional method of obtaining a perfect fit-up requires several workers, many adjustments, and lengthy experimentation with possible solutions. The FIT RITE System enables pipe fitters and fabricators to obtain precise positioning of components independently in most applications. This system makes alignment operations simpler so one person can execute tasks that required multiple workers in the past.

Independent usage of this system results in better productivity and better operation flow throughout job sites. Investing in the FIT RITE System leads to lower labor expenses which produces cost-efficient projects at the same standard of assembly final quality. The FIT RITE System allows Qatar-based companies to minimize their dependency on additional personnel, they can allocate their workforce to critical aspects of pipe fabrication.

Significant Time Savings and Fast Return On Investment for Pipe Fitters and Fabricators

In the pipe fitting and fabrication business time serves as an important component compared to financial resources. Delayed accurate fit-up processes lead to the consumption of more project resources thus resulting in elevated project expenditures. The FIT RITE System accelerates pipe fitter and fabricator fit-up scheduling so their tasks finish more quickly with increased accuracy levels.

The system provides first-time success in fast and precise alignments by eliminating the requirement to readjust and use manual clamps and measure repeatedly. Companies that want to boost their efficiency and profits should consider this tool because it generates excellent ROI through time savings in the fit-up process.

Minimizing the Need for Traditional Fit-Up Tools

The conventional fit-up process relies on various tools such as clamps along with wedges, spacers, and measurement devices yet these tools need frequent adjustments during the process. The FIT RITE System reduces the requirements for traditional fit-up tools which results in alignment process efficiency and tool-related cost reduction.

The system designs automatically deliver precise pipe alignments to maintain constant fit-up procedures which reduces human errors. Workplace safety improves when employees no longer must handle a multitude of equipment because the need for such tools minimizes during alignment procedures.

Productivity and Quality in the Pipe Fabrication Industry

Operation excellence in Qatar relies on precise and efficient pipe fabrication practices for its construction, oil, and gas sectors as well as its industrial sector. The FIT RITE System empowers various industries to work more efficiently through better work quality while simultaneously minimizing project expenses.

Conclusion

Qatar companies that implement the FIT RITE System into their operations will gain better productivity while saving costs. The system stands as the essential solution for achieving precise and faultless pipe fit-ups for pipe fitters and fabricators.